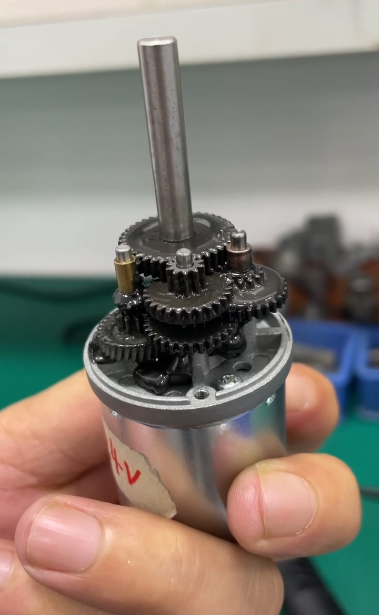

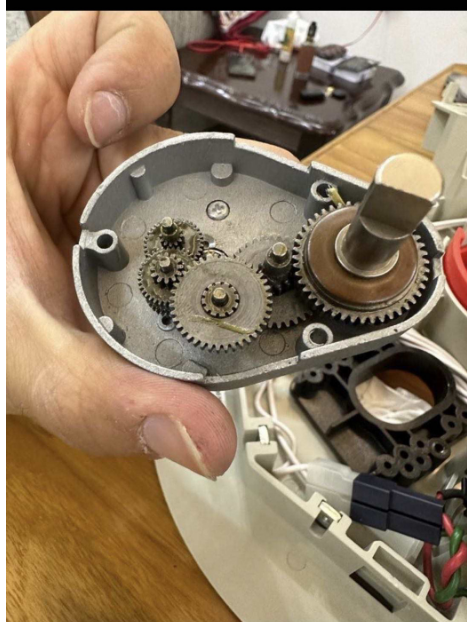

Umgomo oyinhloko wokusebenza we-I-micro reduction gear motorukunciphisa ijubane futhi andise torque ngokusebenzisa gear transmission. .Izinjini zokunciphisa ama-Microsebenzisa ukudluliswa kwamapheya egiya kuwo wonke amazinga ukuze ufeze inhloso yokunciphisa isivinini. Isibonelo, igiya elincane elishayela igiya elikhulu lingafinyelela umphumela othile wokunciphisa. Ngesakhiwo esinezigaba eziningi, isivinini singancishiswa kakhulu. Lesi simiso sokusebenza sivumela ama-motor okunciphisa amancane ukuthi adlale indima ebalulekile ezinhlelweni ezidinga isivinini esiphansi kanye ne-torque ephezulu.

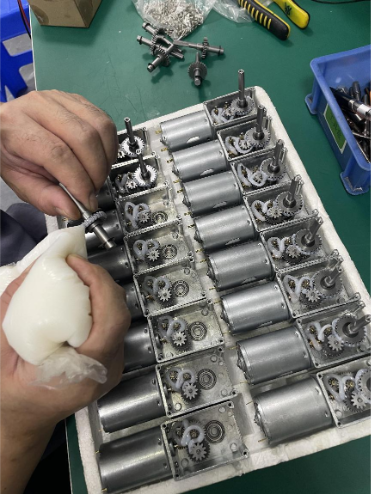

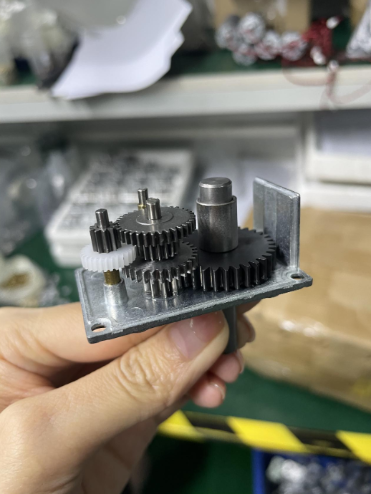

Ukusetshenziswa kwamagiya kuama-micro gear motorskubonakala kakhulu ekwakhekeni nasekusebenzeni kwazo. .Injini yokunciphisa igiya elincaneyin ai-micro motoridivayisi yokunciphisa ukudluliswa kwemishini evaliwe, ngokuvamile ehlanganiswa futhi ihlinzekwe ngumkhiqizi wezimoto zokunciphisa uchwepheshe. Le nhlanganisela ayikwazi ukunciphisa isivinini kuphela futhi yandise i-torque, kodwa futhi inezici zokusetshenziswa kwamandla aphansi, ukusebenza okuphakeme, ukudlidliza okuncane nomsindo ophansi. Umgomo wesakhiwo sesinciphisi segiya uhlanganisa inhlanganisela yegiya lelanga kanye negiya leplanethi, elifinyelela isilinganiso esiphezulu sokunciphisa ngokudluliswa kwegiya elinezigaba eziningi ukuze kuhlangatshezwane nezidingo zokusebenza zemishini ehlukahlukene.

Izinkambu zokufaka izicelo zama-micro reduction motors zibanzi kakhulu. Isetshenziswa kakhulu emishinini emincane yezimboni ekhanyayo, okokusebenza ezishintshayo, izinto zikagesi zasendlini neminye imikhakha. Isibonelo, emishinini elula yezimboni embonini yokupakisha, yokudla, yendwangu nezimonyo,ama-micro-geared motorsingathuthukisa ukusebenza kahle. Emishinini ye-automation, ikakhulukazi imigqa yokukhiqiza,ama-micro gear motorsbadlale indima ebalulekile ngokulungisa isivinini sabo ngokwezidingo zabasebenzisi. Ngaphezu kwalokho, ekusetshenzisweni kwemishini yasendlini njengemishini yobisi lwesoya, amajusi, iziqandisi, nemishini yokuwasha, ama-micro reduction motors ahlinzeka ngokusebenza nokusebenza okuzinzile.

Ukwenza nokulinganisa ekukhiqizeni i-MIM encane

Isondo legiya liyingxenye engaphakathi kwedivayisi yokudlulisa amandla edlulisela amandla ajikelezayo kwelinye igiya noma idivaysi futhi liyingxenye yomshini yokuma okunembe okuphezulu. Eminyakeni yamuva ezinye izinqubo ezithuthukisiwe zokukhiqiza izinto ezincane kanye namagiya amancane enziwe ngezinsimbi nezinye izitsha zobumba ezithuthukisiwe zenziwe [1].Imishini yegiya yeplanethi encanezenziwe futhi ngezingilazi ze-nickel-ferrous (Ni-Fe) kanye nezingilazi zensimbi eziyinqwaba ezisuselwa ku-nickel nge-X-ray lithography & electro-deposition (direct-LIG) [2] kanye nokubumba komjovo [3], ngokulandelana. /

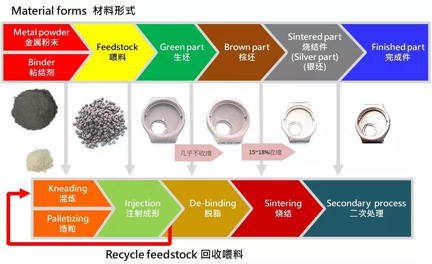

Kodwa-ke, kunesidingo samagiya amancane enziwe ngezinto ezihlala isikhathi eside ezihloselwe ukwenza i-miniaturization kanye nokwenza ngcono ukuthembeka kwemikhiqizo ehlukahlukene. Ngokwemibandela yokukhiqiza inhloso wukuzuza ukusebenza kahle komnotho ukuze kwaneliswe isidingo sezimboni. Ukubumba komjovo we-Micro metal powder (μ MIM) kuyasiza ekukhiqizeni izingxenye ezinosayizi omncane kanye ne-microstructured [4-5], kodwa ukulinganisa ukunemba kwamagiya amancane akhiqizwa yi-μ MIM kube nzima. /

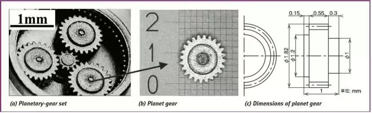

A i-micro-planetary geareyenziwe ngensimbi engagqwali engu-17-4PH yakhiwe ngu-μ MIM njengengxenye yephrojekthi ye-Osaka. Izinga legiya leplanethi elihlangene kakhulu lahlolwa ngokulinganisa ukuhluka kobukhulu bamazinyo egiya ngokuhlaziywa kwesithombe sedijithali. Ii-micro-planetary geareyakhiwe ngezinhlobo ezintathu zamasondo egiya akhiqizwa inqubo ye-μ MIM iboniswa kuMfanekiso1. Kulolu cwaningo, ukunemba kwegiya leplanethi enobukhulu obuboniswe kuMfanekiso 1(c) kwahlolwa. Ukucaciswa kwegiya leplanethi (njengoba sintered) kukhonjiswe kuThebula 1. /

Umfanekiso 1. I-Micro-planetary-gear eyenziwe ngu-μ MIM. (a). Isethi yamaplanethi-gear; (b) . Imishini yeplanethi; (c). Ubukhulu begiya leplanethi /

Ithebula 1. Ukucaciswa kwegiya leplanethi (njenge-sintered). Izinto ezisetshenziselwa ukukhiqiza amagiya ama-ultra-compact kwakuyinsimbi engagqwali engu-17-4PH impushana yamanzi e-atomized (D50=2μm) kanye nezibophezelo ezisekelwe ku-poly-acetyl. Ukulayishwa kwempushana kwe-feedstock kwaba ngu-60vol%. I-feedstock yayibunjwe ngomjovo kusetshenziswa umshini wokubumba umjovo onesivinini esikhulu (FANUC Ltd., S-2000i 50A). Ama-compact aluhlaza aboshwa ku-600ºC amahora amabili endaweni ye-nitrogen, futhi afakwa ku-1150ºC amahora amabili ngaphansi kwe-argon. Izingxenye ze-sintered nazo zaqiniswa ngobudala ku-480ºC ihora elilodwa. /

Ukunemba kwamagiya anosayizi ojwayelekile ngokuvamile kuhlolwa ngokuhlolwa kwe-master gear meshing noma i-profilometry yokuxhumana. Kodwa-ke, endabeni yamagiya ahlangene kunzima ukwenza igiya eliyinhloko kanye nokulinganisa ukuma ngokuthintana. Ngakho-ke indlela yokulinganisa umumo ongaxhumene nayo kusetshenziswa amathuluzi athuthukile njengenzwa yokususwa kwe-laser nokuhlaziywa kwesithombe sedijithali kuthathwa njengewusizo ekuhloleni ukunemba kwamagiya e-ultracompact. /

Isikhathi sokuthumela: Oct-14-2024