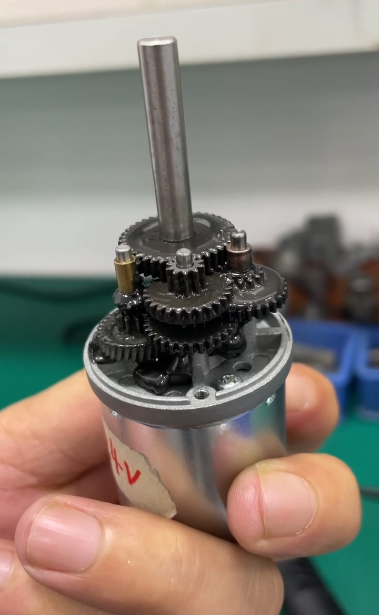

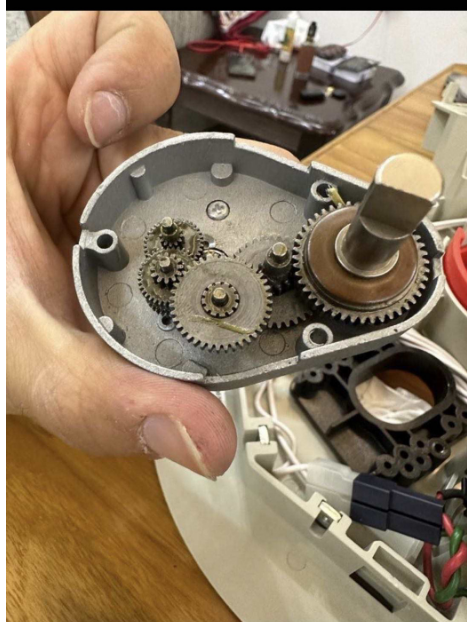

Umgaqo ongundoqo wokusebenza weinjini yokunciphisa i-microkukunciphisa isantya kunye nokunyusa i-torque ngokusebenzisa ukuhanjiswa kwegiya. ...Iinjini zokunciphisa iMicrosebenzisa ukuhanjiswa kwezibini zegiya kuwo onke amanqanaba ukufezekisa injongo yokunciphisa isantya. Ngokomzekelo, i-gear encinci eqhuba i-gear enkulu inokufezekisa umphumo othile wokunciphisa. Ngokusebenzisa i-multi-stage structure, isantya sinokuncitshiswa kakhulu. Lo mgaqo wokusebenza uvumela iimotor zokunciphisa ezincinci ukuba zidlale indima ebalulekileyo kwizicelo ezifuna isantya esiphantsi kunye netorque ephezulu.

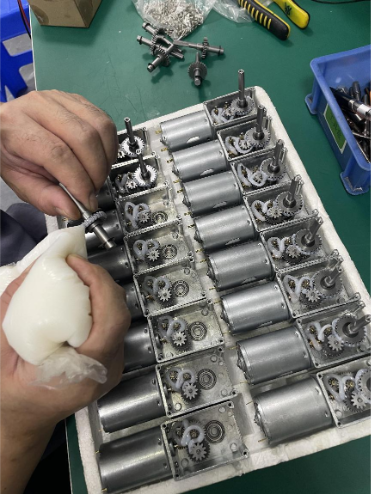

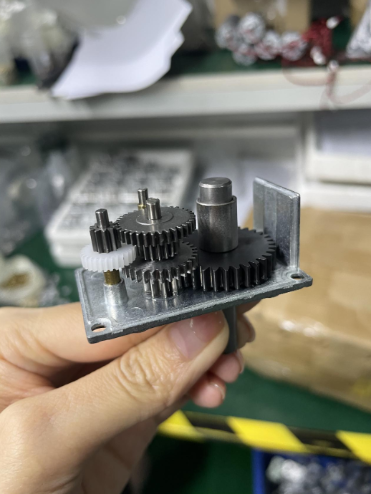

Ukusetyenziswa kweegiya kwiiimotor zegiya ezincinciibonakaliswa ikakhulu kulwakhiwo kunye nomsebenzi wazo. ...Injini yokunciphisa izixhobo ezincinciyimicro motor-eqhutywaisixhobo esivaliweyo sokunciphisa usulelo, esidla ngokudityaniswa kwaye sibonelelwe ngumenzi wemoto oqeqeshiweyo. Olu luhlu alukwazi ukunciphisa kuphela isantya kunye nokwandisa i-torque, kodwa luneempawu zokusetyenziswa kwamandla aphantsi, ukusebenza okuphezulu, ukungcangcazela okuncinci kunye nengxolo ephantsi. Umgaqo wobume bomnciphisi wegiya ubandakanya ukudityaniswa kwegiya yelanga kunye negiya yeplanethi, efikelela kumlinganiselo ophezulu wokunciphisa ngokuhanjiswa kwegiya enamanqanaba amaninzi ukuhlangabezana neemfuno zokusebenza zezixhobo ezahlukeneyo zoomatshini.

Iinkalo zokusetyenziswa kweenjini zokunciphisa ezincinci zibanzi kakhulu. Isetyenziswa kakhulu koomatshini abancinci bemizi-mveliso, izixhobo ezizisebenzelayo, izixhobo zasekhaya kunye namanye amacandelo. Umzekelo, koomatshini abalula kwimizi-mveliso yokupakisha, ukutya, amalaphu kunye nezokuthambisa,iimotor ezine-micro-gearedinokuphucula ukusebenza kakuhle. Kwizixhobo ezizenzekelayo, ngakumbi imigca yokuvelisa,iimotor zegiya ezincincibadlale indima ebalulekileyo ngokulungisa isantya sabo ngokweemfuno zabasebenzisi. Ukongeza, kwizicelo zezixhobo zasekhaya ezinje ngoomatshini bobisi lwesoya, iijusi, iifriji, iifriji, kunye noomatshini bokuhlamba, iimoto ezincinci zokunciphisa zibonelela ngokusebenza okuzinzileyo kunye nokusebenza.

Ukwenza kunye nokulinganisa kwi-MIM encinci yokwenziwa

Ivili legiya licandelo elingaphakathi kwesixhobo sothumelo esithumela amandla ajikelezayo kwesinye isixhobo okanye isixhobo kwaye ikwayinto yomatshini wokubekwa kwindawo echaneke kakhulu. Kwiminyaka yakutsha nje ezinye iinkqubo eziphambili zokwenziwa kwezinto ezincinci kunye nezixhobo ezinobungakanani obuncinci ezenziwe ngesinyithi kunye nezinye iiseramikhi eziphambili zenziwe [1].Iimotor zegiya zeplanethi encincizenziwe kwakhona kwi-nickel-ferrous (Ni-Fe) kunye ne-nickel-based bulk metallic glasses nge-X-ray lithography & electro-deposition (direct-LIG) [2] kunye ne-injection molding [3], ngokulandelanayo. /

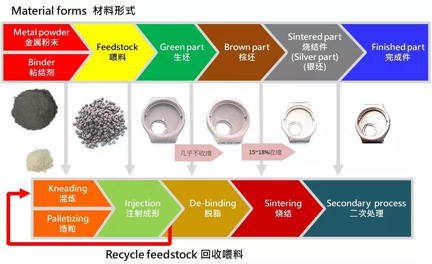

Nangona kunjalo, kukho imfuneko yeegiya ze-micronized ezenziwe ngezinto eziqhelekileyo-injongo ehlala ixesha elide yokwenza i-miniaturization kunye nokuphucula ukuthembeka kweemveliso ezahlukeneyo. Kwimiba yokwenziwa kwemveliso injongo kukufumana impumelelo ephezulu kwezoqoqosho ukwanelisa imfuno yemizi-mveliso. Ukubumba inaliti yomgubo wentsimbi encinci (μ MIM) iluncedo ekuveliseni ubungakanani obuncinci kunye nenxalenye ye-microstructured [4-5], kodwa ukulinganisa ukuchaneka kweegiya ezincinci ezenziwe ngu-μ MIM kuye kwabonakala kunzima. /

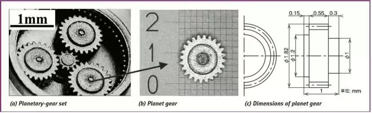

A izixhobo ezincinci zeplanethieyenziwe nge-17-4PH yensimbi engenasici yenziwe ngu-μ MIM njengenxalenye yeprojekthi ye-Osaka. Umgangatho wegiya yeplanethi ye-ultra-compact yavavanywa ngokulinganisa ukwahluka kwimilinganiselo yamazinyo egiya ngohlalutyo lwemifanekiso yedijithali. Iizixhobo ezincinci zeplanethiyenziwe ziintlobo ezintathu zamavili egiya enziwe yinkqubo yeMIM ye-μ iboniswe kuMfanekiso1. Kule sifundo, ukuchaneka kwezixhobo zeplanethi kunye nemilinganiselo eboniswe kwi-Figure 1 (c) ihlolwe. Ukucaciswa kwezixhobo zeplanethi (njengoko sintered) kuboniswe kwiTheyibhile 1. /

Umzobo 1. I-Micro-planetary-gear eyenziwe ngu-μ MIM. (a). Iseti yezixhobo zePlanethi; (b) . Izixhobo zePlanethi; (c). Imilinganiselo yezixhobo zeplanethi /

Itheyibhile 1. Ukucaciswa kwezixhobo zeplanethi (njenge-sintered) .Izixhobo ezisetyenziselwa ukuvelisa i-ultra-compact gears yayiyinsimbi engenasici ye-17-4PH yamanzi e-atomized powder (D50 = 2μm) kunye ne-poly-acetyl based binders. Ukulayishwa komgubo kwi-feedstock ibe yi-60vol. I-feedstock yayiyi-injection-molded usebenzisa umatshini wokubumba we-high-speed injection (FANUC Ltd., S-2000i 50A). Iicompacts eziluhlaza zaye zadityaniswa kwi-600ºC iiyure ezimbini kwi-nitrogen emoyeni, kwaye zifakwe kwi-1150ºC iiyure ezimbini phantsi kwe-argon. Amalungu atshisiweyo nawo aqiniswa bubudala kwi-480ºC iyure enye. /

Ukuchaneka kweegiya ezinobungakanani obuqhelekileyo zivandlakanywa luvavanyo lwe-master gear meshing okanye iprofilometry yoqhagamshelwano. Nangona kunjalo, kwimeko ye-compact gears kunzima ukwenza i-master gear kunye nokulinganisa imilo ngoqhagamshelwano. Ke ngoko indlela yokulinganisa imilo engaqhagamshelwanga kusetyenziswa izixhobo ezikumgangatho ophezulu ezinje ngelaser displacement sensing kunye nohlalutyo lomfanekiso wedijithali zibonwa ziluncedo ekuvavanyeni ukuchaneka kweegiya ze-ultracompact. /

Ixesha lokuposa: Oct-14-2024