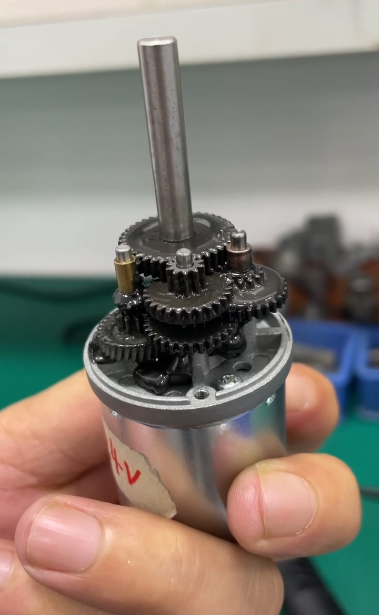

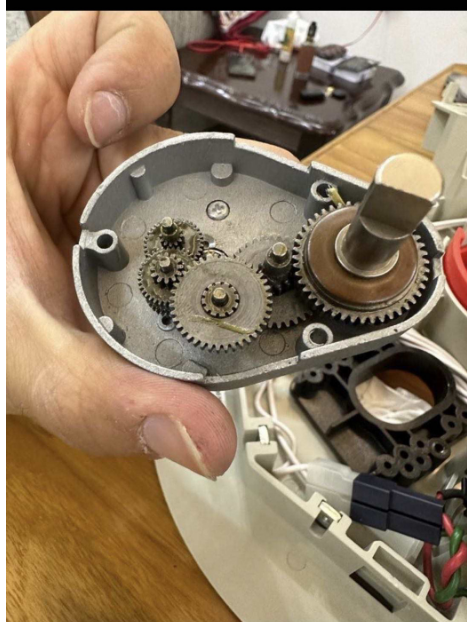

Molao-motheo oa ts'ebetso ea mantlhaenjene ea lisebelisoa tse fokotsang microke ho fokotsa lebelo le ho eketsa torque ka phetiso ea lisebelisoa. "Li-motors tsa ho fokotsa li-microsebelisa phetiso ea lipara tsa lisebelisoa maemong ohle ho fihlela sepheo sa ho fokotsa lebelo. Ka mohlala, gear e nyenyane e khanna koloi e kholo e ka finyella phello e itseng ea ho fokotsa. Ka sebopeho sa mekhahlelo e mengata, lebelo le ka fokotsoa haholo. Molao-motheo ona oa ts'ebetso o lumella li-motor tse fokotsang ho bapala karolo ea bohlokoa lits'ebetsong tse hlokang lebelo le tlase le torque e phahameng.

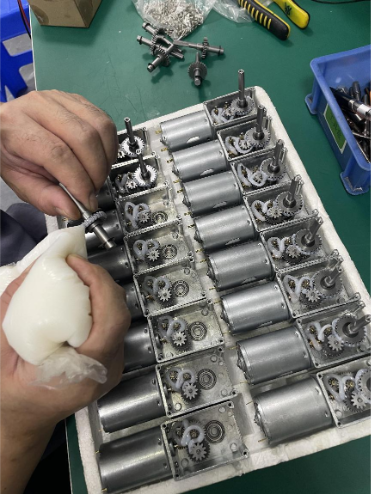

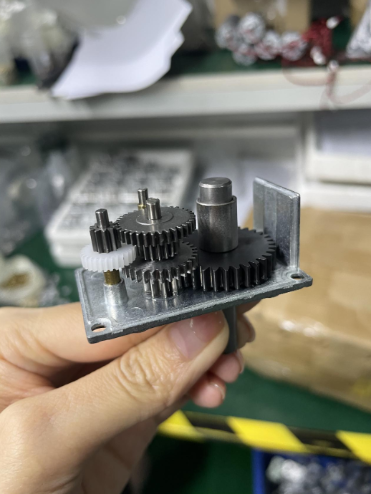

Tšebeliso ea lisebelisoa holi-motors tsa micro geare bonahatsoa haholo ke sebopeho le tšebetso ea tsona. "Enjene ea ho fokotsa lisebelisoa tse nyaneke ae tsamaisoang ka enjene e nyanesesebelisoa sa phokotso ea phetisetso e koetsoeng, eo hangata e bokelloang le ho fanoa ke moetsi oa likoloi oa profeshenale. Motsoako ona o ke ke oa fokotsa lebelo feela le ho eketsa torque, empa hape o na le litšobotsi tsa tšebeliso e tlaase ea matla, ts'ebetso e phahameng, ho sisinyeha ho nyenyane le lerata le tlaase. Molao-motheo oa sebopeho sa mochini o fokotsang li-gear o kenyelletsa motsoako oa lisebelisoa tsa letsatsi le lisebelisoa tsa polanete, tse fihlelang tekanyo e phahameng ea phokotso ka phetisetso ea li-gear tsa mekhahlelo e mengata ho fihlela litlhoko tsa ts'ebetso tsa lisebelisoa tse fapaneng tsa mochini.

Libaka tsa ts'ebeliso ea li-motor tse fokotsang li pharalletse haholo. E sebelisoa haholo mecheng e menyenyane ea indasteri e bobebe, lisebelisoa tsa boiketsetso, lisebelisoa tsa lapeng le likarolo tse ling. Mohlala, mochining o bobebe oa indasteri indastering ea ho paka, lijo, masela le litlolo,li-motor tse nang le lisebelisoa tse nyanee ka ntlafatsa katleho ea mosebetsi. Ka thepa ea boiketsetso, haholo mehala ea tlhahiso,li-motors tsa micro gearphetha karolo ea bohlokoa ka ho fetola lebelo la bona ho latela litlhoko tsa basebelisi. Ntle le moo, lits'ebetsong tsa lisebelisoa tsa lapeng tse joalo ka mechini ea lebese la soya, li-juicer, lihatsetsi le mechini ea ho hlatsoa, li-motor tse fokotsang li fana ka ts'ebetso le ts'ebetso e tsitsitseng.

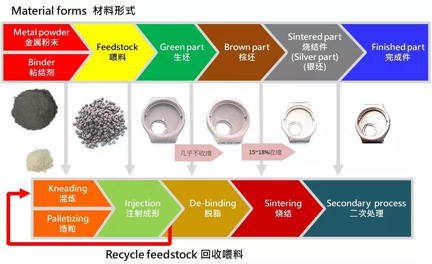

Ho etsa le ho metha ka tlhahiso ea micro MIM

Gearwheel ke karolo e ka hare ho sesebelisoa sa phetisetso se fetisetsang matla a potolohang ho gear kapa sesebelisoa se seng hape ke karolo ea mochini bakeng sa boemo bo nepahetseng bo holimo. Lilemong tsa morao tjena ho entsoe mekhoa e meng e tsoetseng pele ea tlhahiso e nyane le likere tse nyane tse entsoeng ka tšepe le lirafshoa tse ling tse tsoetseng pele [1].Li-motors tsa li-microplanetary gearli boetse li entsoe ho tloha ho nickel-ferrous (Ni-Fe) le likhalase tsa tšepe tse ngata tse thehiloeng ho nickel ka X-ray lithography & electro-deposition (direct-LIG) [2] le molding ea ente [3], ka ho latellana. /

Leha ho le joalo, ho na le tlhoko ea likere tse nyane tse entsoeng ka lisebelisoa tse tšoarellang ka kakaretso bakeng sa miniaturization le ntlafatso ea ts'epo ea lihlahisoa tse fapaneng. Mabapi le tlhahiso sepheo ke ho fihlela katleho e phahameng ea moruo ho khotsofatsa tlhoko ea indasteri. Micro metal powder injection molding (μ MIM) e na le thuso bakeng sa ho hlahisa likarolo tse nyenyane le tse nyenyane [4-5], empa ho lekanya ho nepahala ha lisebelisoa tse nyenyane tse entsoeng ke μ MIM ho ipakile ho le thata. /

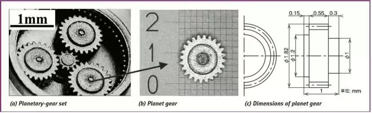

A lisebelisoa tsa microplanetarye entsoeng ka tšepe e sa hloekang ea 17-4PH e entsoe ke μ MIM e le karolo ea morero oa Osaka. Boleng ba lisebelisoa tsa polanete ea ultra-compact bo ile ba lekoa ka ho lekanya phapang ea litekanyo tsa meno a gear ka tlhahlobo ea litšoantšo tsa dijithale. Thelisebelisoa tsa microplanetarye entsoe ka mefuta e meraro ea li-gearwheel tse entsoeng ke μ MIM ts'ebetso e bonts'itsoe ho Figure1. Phuputsong ena, ho nepahala ha lisebelisoa tsa polanete tse nang le litekanyo tse bontšitsoeng ho Setšoantšo sa 1 (c) ho ile ha hlahlojoa. Tlhaloso ea lisebelisoa tsa polanete (joaloka sintered) e bontšoa ho Lethathamo la 1. /

Setšoantšo sa 1. Micro-planetary-gear e entsoeng ke μ MIM. (a). Sete ea lipolanete-gear; (b) . Lisebelisoa tsa polanete; (c). Litekanyo tsa lisebelisoa tsa polanete /

Letlapa la 1. Tlhaloso ea lisebelisoa tsa polanete (e le sintered) . Thepa e sebelisetsoang ho hlahisa li-ultra-compact gears e ne e le tšepe e sa hloekang ea 17-4PH phofo e entsoeng ka metsi (D50 = 2μm) le li-binders tse thehiloeng ho poly-acetyl. Phahamiso ea phofshoana ea phepelo e ne e le 60vol%. Sehlahisoa sa phepelo se ne se entsoe ka ente ho sebelisoa mochini oa ho bopa ka lebelo le phahameng (FANUC Ltd., S-2000i 50A). Li-compact tse tala li ile tsa tlosoa ho 600ºC ka lihora tse peli sebakeng sa naetrojene, 'me tsa sintered ka 1150ºC lihora tse peli tlas'a argon. Likarolo tse sintered le tsona li ile tsa thatafatsoa ke lilemo ho 480ºC ka hora e le 'ngoe. /

Ho nepahala ha likere tse boholo bo tloaelehileng hangata ho hlahlojoa ka tlhahlobo ea master gear meshing kapa contact profilometry. Leha ho le joalo, tabeng ea li-gear tse kopanetsoeng ho thata ho etsa lisebelisoa tsa master le ho lekanya sebopeho ka ho kopana. Ka hona, mokhoa oa ho lekanya sebopeho o sa amaneng o sebelisa lisebelisoa tse tsoetseng pele joalo ka laser displacement sensing le tlhahlobo ea litšoantšo tsa dijithale li nkuoa li le molemo ho lekola ho nepahala ha likere tsa ultracompact. /

Nako ea poso: Oct-14-2024