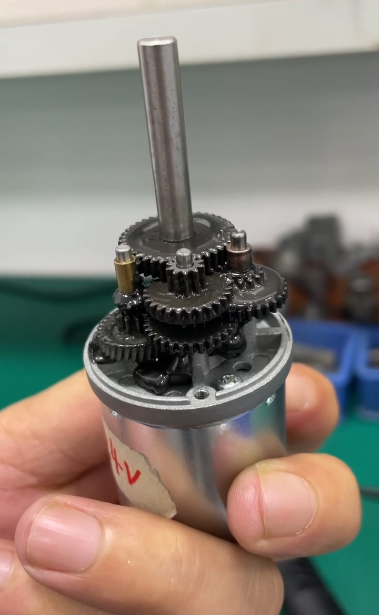

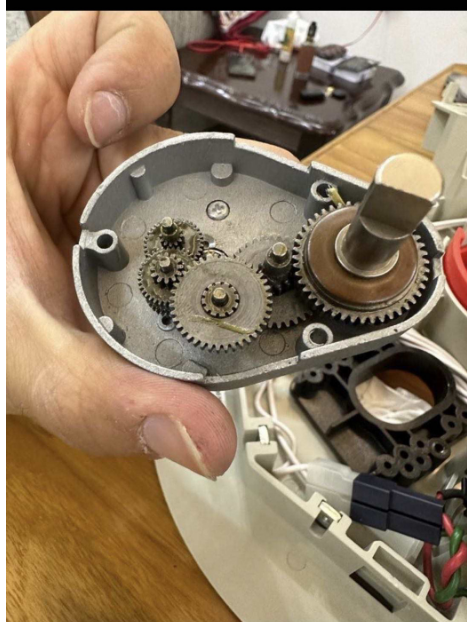

Lub hauv paus ntsiab lus ntawm kev ua haujlwmmicro txo gear motoryog kom txo tau qhov ceev thiab nce lub torque los ntawm iav kis tau tus mob. covMicro txo motorssiv kev sib kis ntawm cov iav khub ntawm txhua qib kom ua tiav lub hom phiaj ntawm kev txo qis. Piv txwv li, lub iav me me tsav lub iav loj tuaj yeem ua tiav qhov txo qis. Los ntawm ntau theem qauv, qhov ceev tuaj yeem txo qis heev. Lub hauv paus ntsiab lus ua haujlwm no tso cai rau micro txo lub cev muaj zog los ua lub luag haujlwm tseem ceeb hauv cov ntawv thov uas xav tau qis qis thiab siab torque.

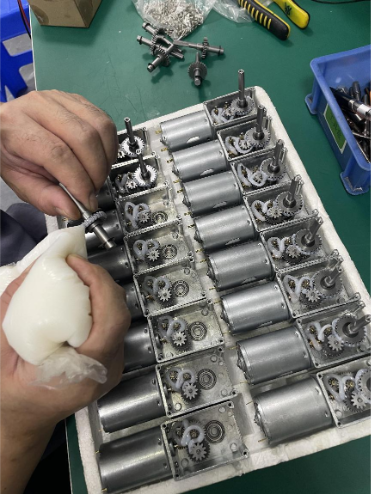

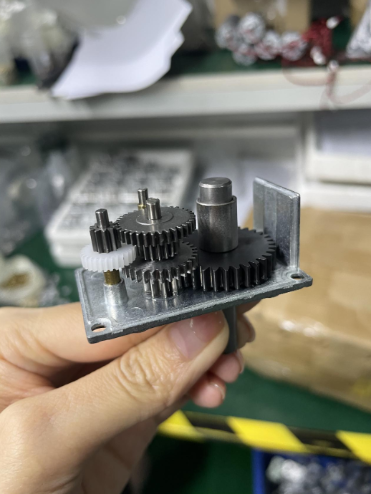

Kev siv cov iav hauvmicro gear motorsyog qhov tseem ceeb ntawm lawv cov qauv thiab kev ua haujlwm. covMicro iav txo lub cev muaj zogyog amicro motor-tsavkaw kis tau tus mob txo cov cuab yeej, uas feem ntau yog sib sau ua ke thiab muab los ntawm cov kws tshaj lij txo lub cev muaj zog tsim khoom. Qhov kev sib xyaw ua ke no tuaj yeem tsis tsuas yog txo qhov ceev thiab nce lub zog, tab sis kuj muaj cov yam ntxwv ntawm kev siv hluav taws xob tsawg, kev ua haujlwm zoo dua, kev co me me thiab tsis muaj suab nrov. Lub hauv paus ntsiab lus ntawm cov iav reducer suav nrog kev sib xyaw ntawm lub hnub iav thiab cov iav planetary, uas ua tiav qhov kev txo qis dua los ntawm ntau theem iav kis tau tus mob kom tau raws li kev xav tau ntawm ntau yam khoom siv tshuab.

Daim ntawv thov teb ntawm micro txo motors yog dav heev. Feem ntau yog siv rau hauv cov khoom siv hluav taws xob me me, cov khoom siv automation, cov khoom siv hauv tsev thiab lwm yam. Piv txwv li, nyob rau hauv lub teeb muaj machinery nyob rau hauv lub ntim, zaub mov, textile thiab tshuaj pleev ib ce industries,micro-geared motorstuaj yeem txhim kho kev ua haujlwm zoo. Hauv cov khoom siv automation, tshwj xeeb tshaj yog cov kab ntau lawm,micro gear motorsua lub luag haujlwm tseem ceeb los ntawm kev kho lawv qhov nrawm raws li cov neeg siv xav tau. Tsis tas li ntawd, hauv kev siv cov khoom siv hauv tsev xws li cov tshuab soymilk, cov kua txiv hmab txiv ntoo, cov tub yees, thiab cov tshuab ntxhua khaub ncaws, micro txo lub cev muaj zog muab kev ua haujlwm ruaj khov thiab ua haujlwm.

Ua thiab ntsuas hauv micro MIM manufacturing

Lub gearwheel yog ib qho khoom siv nyob rau hauv ib qho khoom siv kis tau tus mob uas xa cov quab yuam sib hloov mus rau lwm lub iav los yog cov cuab yeej thiab tseem yog lub tshuab siv rau qhov tseeb qhov chaw. Nyob rau hauv xyoo tas los no qee cov txheej txheem micro-tsim siab heev thiab cov iav me me ua los ntawm cov hlau thiab qee cov ceramics siab heev tau tsim [1].Micro-planetary iav motorskuj tau ua los ntawm nickel-ferrous (Ni-Fe) thiab nickel-based bulk metallic tsom iav los ntawm X-ray lithography & electro-deposition (direct-LIG) [2] thiab txhaj tshuaj molding [3], raws li. /

Txawm li cas los xij, muaj kev thov rau cov iav micronized ua los ntawm cov khoom siv dav dav rau cov khoom siv me me thiab kev txhim kho kev ntseeg tau ntawm ntau yam khoom. Hauv kev tsim khoom lub hom phiaj yog kom ua tiav kev lag luam siab kom ua tau raws li kev xav tau ntawm kev lag luam. Micro hlau hmoov txhaj tshuaj molding (μ MIM) yog qhov tseem ceeb rau kev tsim cov micro-sized thiab microstructured qhov chaw [4-5], tab sis kev ntsuas qhov tseeb ntawm micro-gears tsim los ntawm μ MIM tau ua pov thawj nyuaj. /

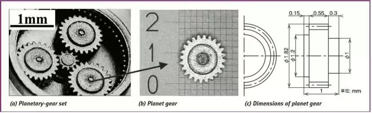

A micro-planetary iavua los ntawm 17-4PH stainless hlau yog tsim los ntawm μ MIM raws li ib feem ntawm Osaka project. Qhov zoo ntawm ultra-compact ntiaj chaw iav tau soj ntsuam los ntawm kev ntsuas qhov sib txawv ntawm qhov ntev ntawm cov iav hniav nrog cov duab tsom xam. Covmicro-planetary iavtsim los ntawm peb hom gearwheels tsim los ntawm μ MIM txheej txheem yog qhia hauv daim duab 1. Hauv txoj kev tshawb no, qhov tseeb ntawm lub ntiaj teb iav nrog qhov ntev qhia hauv daim duab 1(c) tau raug soj ntsuam. Cov specification ntawm lub ntiaj teb iav (raws li sintered) yog qhia nyob rau hauv Table 1. /

Daim duab 1. Micro-planetary-iav tsim los ntawm μ MIM. (a). Planetary-iav teeb; (b). Planet iav; (c). Dimensions ntawm lub ntiaj teb iav /

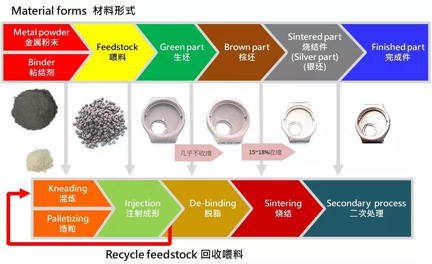

Table 1. Specification ntawm lub ntiaj teb iav (raws li sintered).Cov ntaub ntawv siv los tsim lub ultra-compact zog yog stainless hlau 17-4PH dej-atomized hmoov (D50 = 2μm) thiab poly-acetyl raws li binders. Hmoov loading ntawm feedstock yog 60vol%. Cov khoom noj khoom haus tau txhaj tshuaj molded siv lub tshuab txhaj tshuaj kub ceev (FANUC Ltd., S-2000i 50A). Cov ntsuab compacts tau de-bound ntawm 600ºC rau ob teev nyob rau hauv ib tug nitrogen cua, thiab sintered ntawm 1150ºC rau ob teev nyob rau hauv argon. Cov sintered qhov chaw kuj muaj hnub nyoog-hardened ntawm 480ºC rau ib teev. /

Qhov tseeb ntawm cov khoom siv sib xyaw ua ke feem ntau yog ntsuas los ntawm tus tswv iav meshing xeem lossis hu rau profilometry. Txawm li cas los xij, nyob rau hauv cov ntaub ntawv ntawm compact gears nws yog ib qho nyuaj rau manufacture tus tswv iav thiab ntsuas cov duab los ntawm kev sib cuag. Yog li no, cov txheej txheem ntsuas cov duab tsis sib txuas siv cov cuab yeej siv siab xws li laser hloov pauv qhov ntsuas thiab ntsuas cov duab digital tau suav tias yog qhov tseem ceeb hauv kev ntsuas qhov tseeb ntawm cov iav ultracompact. /

Post lub sij hawm: Oct-14-2024