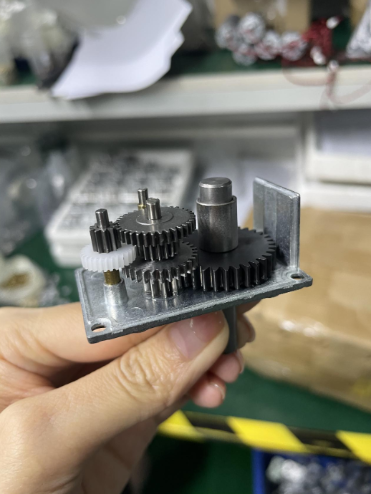

Babban ka'idar aiki namicro rage gear motorshi ne don rage gudu da kuma ƙara karfin juyi ta hanyar watsa kaya. "Micro rage Motorsyi amfani da watsa nau'i-nau'i na kaya a kowane matakai don cimma manufar rage saurin gudu. Alal misali, ƙaramin kayan aiki yana tuƙi babban kayan aiki zai iya cimma wani tasiri na raguwa. Ta hanyar tsarin matakai da yawa, ana iya rage saurin gudu sosai. Wannan ka'idar aiki tana ba da damar ƙananan injunan raguwa don taka muhimmiyar rawa a cikin aikace-aikacen da ke buƙatar ƙananan gudu da babban karfin wuta.

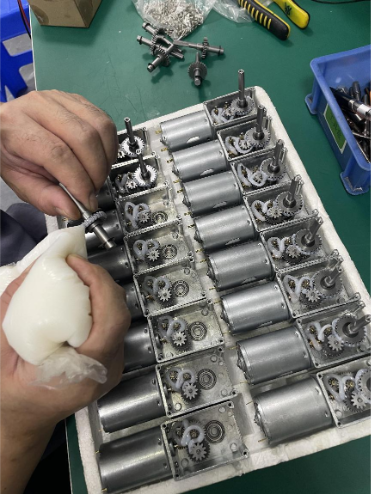

Aikace-aikacen gears a cikinmicro gear Motorsyafi bayyana a tsarinsu da aikinsu. "Motar rage yawan kayan aikini amicro-motarufaffiyar na'urar rage watsawa, wacce ƙwararrun ƙwararrun masana'anta ke haɗawa da samarwa. Wannan haɗin gwiwa ba zai iya rage gudu kawai ba kuma yana ƙara yawan karfin, amma har ma yana da halaye na rashin amfani da makamashi, aikin da ya fi dacewa, ƙananan rawar jiki da ƙananan amo. Tsarin tsari na mai rage kayan aiki ya haɗa da haɗuwa da kayan aikin rana da kayan aiki na duniya, wanda ke samun raguwa mafi girma ta hanyar watsa kayan aiki da yawa don saduwa da bukatun aiki na kayan aikin injiniya daban-daban.

Filayen aikace-aikacen injinan rage ƙananan ƙananan suna da faɗi sosai. Ana amfani da shi a cikin ƙananan injunan masana'antu masu haske, kayan aiki na atomatik, na'urorin gida da sauran fannoni. Misali, a cikin injinan masana'antu masu haske a cikin marufi, abinci, masana'anta da masana'antar kayan kwalliya,ƙananan motocizai iya inganta ingantaccen aiki. A cikin kayan aikin atomatik, musamman layin samarwa,micro gear Motorstaka muhimmiyar rawa ta hanyar daidaita saurin su bisa ga bukatun mai amfani. Bugu da kari, a cikin aikace-aikacen kayan aikin gida kamar injin waken soya, juicers, firji, da injin wanki, ƙananan injin rage ragewa suna ba da ingantaccen aiki da aiki.

Yin da aunawa a masana'antar micro MIM

Gearwheel wani sashi ne a cikin na'urar watsawa wanda ke watsa ƙarfin jujjuyawa zuwa wani kayan aiki ko na'ura kuma shine mashin na'ura don daidaita daidaitaccen matsayi. A cikin 'yan shekarun nan an ƙera wasu ci-gaban hanyoyin sarrafa ƙananan ƙwayoyin cuta da ƙananan gears da aka yi da ƙarfe da wasu tukwane na ci gaba [1].Micro-planetary gear MotorsHakanan an yi su daga nickel-ferrous (Ni-Fe) da gilashin ƙarfe na tushen nickel ta X-ray lithography & deposition electro-deposition (direct-LIG) [2] da allura gyare-gyare [3], bi da bi. /

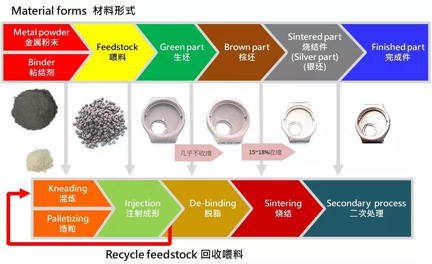

Koyaya, akwai buƙatun kayan aikin micronized da aka yi da kayan ɗorewa gabaɗaya don ƙaranci da ingantaccen amincin samfuran daban-daban. A cikin sharuddan masana'antu, manufar ita ce cimma ingantaccen ingantaccen tattalin arziki don biyan bukatun masana'antu. Micro karfe allura gyare-gyaren foda (μ MIM) yana da amfani don samar da ƙananan ƙananan sassa da ƙananan sassa [4-5], amma auna daidaiton micro-gears da μ MIM ke ƙera ya tabbatar da wahala. /

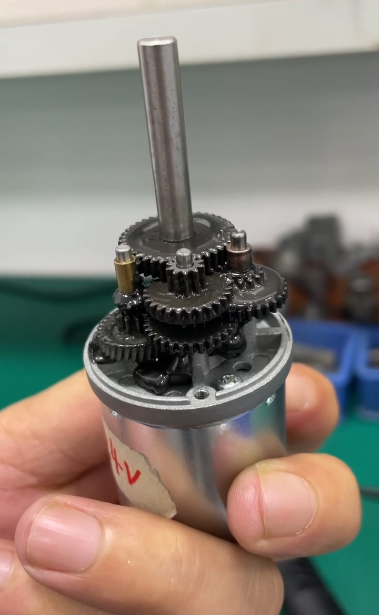

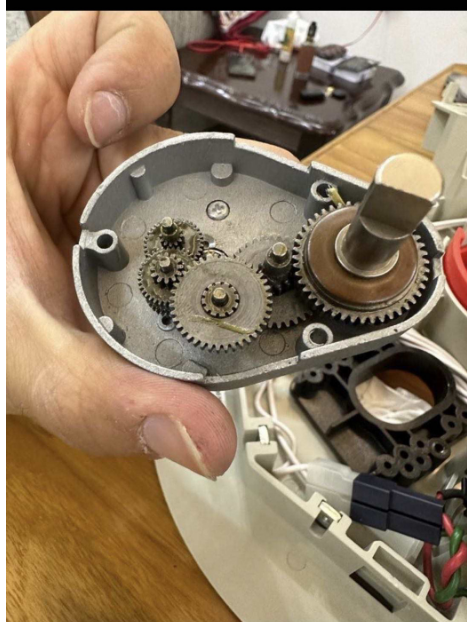

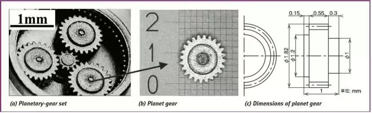

A micro-planetary kayawanda aka yi da bakin karfe 17-4PH μ MIM ne ya kera shi a matsayin wani bangare na aikin Osaka. An kimanta ingancin ingantattun kayan aikin duniya ta hanyar auna bambancin girman haƙoran gear tare da nazarin hoto na dijital. Themicro-planetary kayawanda ya ƙunshi nau'ikan gearwheels guda uku da aka kera ta hanyar μ MIM ana nuna su a cikin Hoto1. A cikin wannan binciken, an kimanta daidaiton kayan aikin duniya tare da ma'auni da aka nuna a cikin Hoto 1 (c). An nuna ƙayyadaddun kayan aikin duniya (kamar yadda aka yi amfani da shi) a cikin Tebur 1. /

Hoto 1. Micro-planetary-gear da μ MIM ke ƙera. (a). Planetary-gear saitin; (b) . Kayan aikin duniya; (c). Girman kayan aikin duniya /

Table 1. Ƙayyadaddun kayan aiki na duniya (kamar yadda aka yi amfani da su) .Ayyukan da aka yi amfani da su don samar da kayan aiki masu mahimmanci sun kasance bakin karfe 17-4PH foda mai atomized foda (D50 = 2μm) da poly-acetyl tushen binders. Load da foda na kayan abinci ya kasance 60volt%. An ƙera kayan abinci da allura ta amfani da injin gyare-gyaren allura mai sauri (FANUC Ltd., S-2000i 50A). An cire koren compacts a 600ºC na sa'o'i biyu a cikin yanayin nitrogen, kuma an yi shi a 1150ºC na sa'o'i biyu a ƙarƙashin argon. Hakanan an ɗora sassan ɓangarorin da aka lalata a 480ºC na awa ɗaya. /

Ana ƙididdige daidaiton girman gears gabaɗaya ta babban gwajin meshing gear ko bayanin martaba. Duk da haka, a cikin yanayin ƙaƙƙarfan gears yana da wuya a kera na'ura mai mahimmanci da kuma auna siffar ta hanyar sadarwa. Don haka dabarar ma'aunin sifar da ba ta tuntuɓar ta ta amfani da na'urori masu ci gaba kamar na'urar gano matsuguni ta Laser da nazarin hoto na dijital ana ɗaukar su da amfani wajen kimanta daidaiton kayan aikin ultracompact. /

Lokacin aikawa: Oktoba-14-2024