32mm Spur Gear Motor

About This Item

A spur gear motor is a type of gear motor that uses spur gears to transfer and amplify power from the motor to the output shaft. Spur gears are cylindrical gears with straight teeth that mesh together to transfer rotational motion. Here are some key features and applications of spur gear motors.

Features:

● Efficiency: Spur gear systems have high mechanical efficiency, typically around 95-98%, making them ideal for applications where maximum power transfer is required.

● Compact and lightweight: Spur gear motors are available in various sizes and can be designed with compact and lightweight constructions, making them suitable for applications with limited space or weight restrictions.

● Simplified design: Spur gears have a simple design and are easy to manufacture, making spur gear motors cost-effective compared to other gear motor types.

● High torque: Spur gear motors can provide high torque output, allowing them to handle heavy loads and applications that require substantial power.

Applications:

1.Robotics: Spur gear motors are commonly used in robot joints and actuators to provide precise and controlled movement.

2.Industrial machinery: Spur gear motors find applications in various industrial machinery, such as conveyor systems, packaging equipment, and automated manufacturing processes.

3.Automotive: Spur gear motors are used in automotive applications like power door locks, power windows, and windshield wiper systems.

4.Appliances: Spur gear motors can be found in home appliances such as washing machines, fans, and kitchen appliances.

5.Medical equipment: Spur gear motors are used in various medical devices, including infusion pumps, surgical instruments, and diagnostic equipment.

6.HVAC systems: Spur gear motors are employed in heating, ventilation, and air conditioning (HVAC) systems for fan control and damper actuation.

Overall, spur gear motors are versatile and widely used in applications that require efficient power transmission and torque delivery.

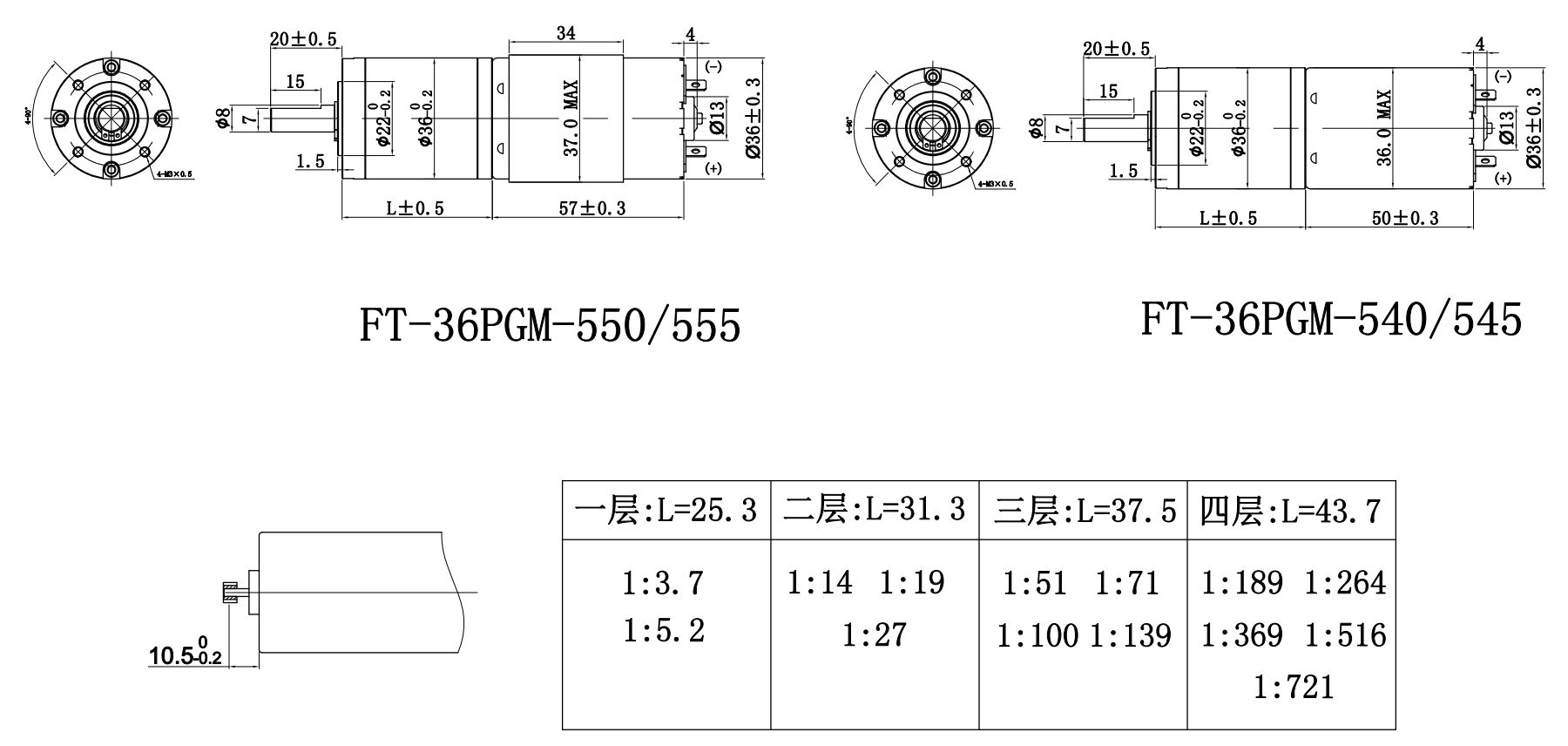

Gear Box Data

| Gear grade |

1 |

2 |

3 |

4 |

| Reduction gear ratio(K) |

3.7、5.2 |

14、19、27 |

54、71、100、139 |

189、264、369、515、721 |

| Gearbox length(mm) |

27.5 |

35.5 |

43.5 |

51.5 |

| Rated torque(kg.cm) |

3 |

6 |

9 |

17 |

| Stall torque(kg.cm) |

6 |

10 |

20 |

35 |

| efficiency(%) |

90% |

81% |

73% |

65% |

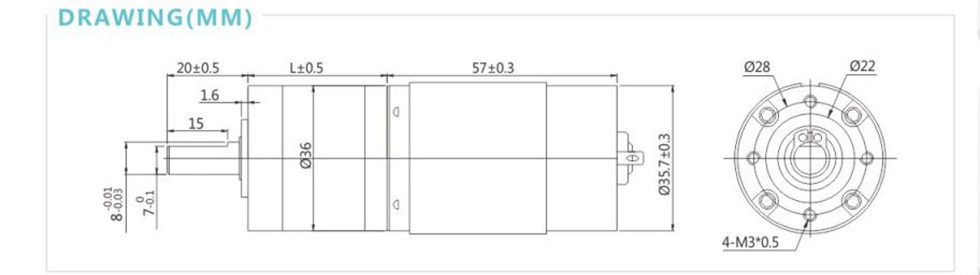

Dimensions and Reduction Ratio

Company Profile